how to test water vapor permeability distribution|water vapor permeance explained : manufacture however, it is not usually the perm rating of the water vapor barrier which determines how much water will pass into the insulation, but the quality of the vapor barrier installation. A carefully installed, well-sealed 4-mil polyethylene vapor barrier is much preferred to a 6-mil vapor barrier with unsealed seams, gaps, tears web23 de mar. de 2022 · 3,2. Usuários. 4,3. Adorocinema. 3,0. Assista agora. John Wick: Um Novo Dia Para Matar (2017) Após recuperar seu carro, John Wick acredita que enfim .

{plog:ftitle_list}

WEB17 de ago. de 2020 · Familia Sacana 74- Comforting her betrayed daughter ~ Incesto. TUFOS 💞 Big Boobs, Blowjob, Daughter, Group, Oldman, Sacana Family, Threesome. 01/08/2020.

Detailed video explanation of ASTM E96-22 standard desiccant and water test methods for water vapor transmission rate of materials.

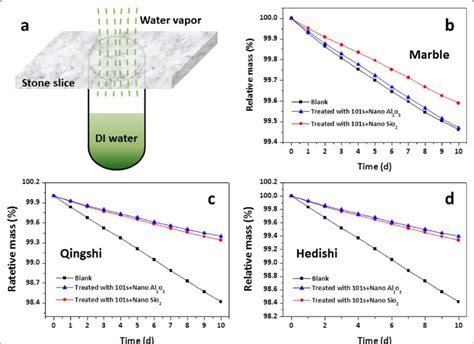

A test bench for moisture exchange of porous membrane (shown in Fig. 4) was used to test water vapor transmembrane permeability. The test results were used to experimentally evaluate the fractal model established above. As shown in Fig. 4, two air streams, one moist and one dry, exchanged moisture through the membrane exchanger. Dry air was .

water vapor transmission rate tester

water vapor transmission rate test

water vapor permeability testing is also introduced. 1.summary of cup method Cup method is the method used to test water vapor permeability independently based on a simple and perspicuous principle. In cup method, there is certain pressure difference maintained on two sides of the specimen. Parameters relating water vapor permeability is . The rate of water vapor transfer for fabric, coated fabrics, composite, clothing, industrial textiles, etc. is ascertained using the water vapor permeability test. Water Vapor Permeability Tester Equipped with a .however, it is not usually the perm rating of the water vapor barrier which determines how much water will pass into the insulation, but the quality of the vapor barrier installation. A carefully installed, well-sealed 4-mil polyethylene vapor barrier is much preferred to a 6-mil vapor barrier with unsealed seams, gaps, tears How does climate impact permeability? In general, water vapor moves from the warm side of a wall to the cold side of a wall. This means that it tends to go from the inside out in northern climates and from the outside in down south. In the middle of the country, part of the year it goes from inside out and part of the year it goes from outside .

The study of permeation and diffusion of gases through polymeric matrices has been of great scientific interest for various applications such as packaging and development of membranes for separation [1, 2].Products such as food, medicines, electronics, photovoltaics, etc, are prone to degradation in the presence of water vapor [3, 4].Therefore, study of oxygen and .Specific test methods for measuring water vapor permeability are given in ASTM Standard E96. For many engineering materials, vapor permeability is a strong function of mean relative humidity. Wet and dry cups cannot adequately characterize this dependence on relative humidity. Instead, a modified cup method can be used, in which pure water or .Yet another test method. Now, let’s look at how we test the permeance of a material using the ASTM E96 “standard test method for water vapor transmission of materials,” which is commonly known as a wet cup/dry cup test. This method reveals some interesting characteristics about how materials behave. Wet cup/dry cup test.Moisture vapor transmission rate (MVTR), also water vapor transmission rate (WVTR), is a measure of the passage of water vapor through a substance.It is a measure of the permeability for vapor barriers.. There are many industries where moisture control is critical. Moisture sensitive foods and pharmaceuticals are put in packaging with controlled MVTR to achieve the required .

Cup experiments are the most widely used method to measure the water vapor permeability of porous building materials. For this test, cup assembly is designed to create a vapor pressure gradient across a sample and, thus, to allow vapor diffusion through it. Water vapor permeability is assessed by weighing cup assembly over time.Keywords: Water vapor permeability; Water vapor transmission rate; Cup method; Membrane; ASTM E96. 1. Introduction The global energy consumption has risen significantly in the past decades due to the growth of population, to the increase in the thermal comfort desire and to the rapidly developing economy. Five testing instruments plus a new test apparatus were employed to evaluate the water vapor transport properties of fabrics with low, medium, and high vapor permeability. The test results show that the desiccant inverted cup method generated the highest water vapor transmission rate, followed by the new method, the dynamic moisture permeation .

To learn more about what permeation is, how it works, and how MOCON Instruments help you find how permeation works, click the link below: https://www.ametekm.It is a valid test for soils with a high rate of flow like sands and gravels, but also some clay soils. Falling Head Test allows the head to decrease as water infiltrates the sample, diminishing the pressure over the course of the test. Falling head methods are generally limited to fine-grained soils. Soil Permeability Testing EquipmentFIELD MANUAL 110 Table 17-1.—A glossary of abbreviations and definitions used in permeability calculations K = Coefficient of permeability in feet (meters) per year under a unit gradient. Q = Steady flow into the well in ft3/sec [m3/sec]. H = The effective head of water in the well in feet (m). For packer tests, determining the effective head is defined

Water Vapor Transmission Rate Testing WVTR testing was performed using a MOCON®* PERMATRAN-W®600 instru-ment, in accordance with ASTM F-1249, Water Vapor Transmission Rate Through Plastic Film and Sheeting Using a Modulated Infrared Sensor. Results are reported in grams/meter2/day for testing at 37.8°C (100°F) and 100% relative humidity. 1 Both ASTM methods determine water vapor transmission rate and permeance of the film to water vapor. Additionally, ASTM F1249 determines water vapor permeability coefficient for homogeneous materials. 3.2.4.1 Gravimetric Method. In this method a known amount of desiccant is placed in an impermeable jar, and the mouth of the jar is covered with . For performance textiles, water vapor permeability is the focus, as it directly impacts the breathability of the fabric. So as a matter of fact, both breathability and permeability relate to a fabric’s ability to manage moisture, ensuring comfort and dryness during physical activities. . BSI – BS 3424-34 Method for testing the water .Permeability of Common Building Material to Water Vapor. EEM-00259 View this publication in PDF form to print or download.. Order a hard copy. WHAT IS A PERM RATING? If a material has a perm rating of 1.0, 1 grain of water vapor will pass through 1 square foot of the material, provided that the vapor pressure difference between the cold side and the warm side of the .

water vapor permeance explained

To study the influence of the mesoporous nanosheets contents on the water vapor permeability and selectivity of the PEBAX matrix membrane, a mixed gas permeability test is carried out containing .The water vapour permeability of the fabric is the loss in weight of water in the cup, expressed in g/m2/day. Since the water vapour permeability is influenced by the still air layer resistance below the fabric, which dominates the total resistance and . Water vapor transmission is a rather confusing issue. The difference in vapor pressure between two sides of a building envelope assembly is the driving force behind vapor transmission. (Although by comparison, gaps in the envelope account for vastly greater amounts moisture migration due to vapor-laden air infiltration.) Vapor = Latent Heat; Air Temperature = .What is water vapor transmission or WVT, the Water Vapor Permeance or WVP, and the Water Vapor Permeability? These three terms are used to describe how quickly water vapor diffuses through a solid material. The Water Vapor Permeance is often simply call the permeance, and the water vapor permeability is often simply called the permeability.

3.2.2.2 Vapor permeability. Water vapor permeability represents the ability of a material to transfer moisture. The cup method is the most widely used method in the literature for measuring this coefficient. The high open porosity of plant-based .The test evaluates the water vapor transfer through semi-permeable and permeable samples. The data can be used by manufacturers and designers and is often important in packaging applications. Test Procedure: A cup is filled with distilled water leaving a small gap (0.75" to 0.25") of air space between the specimen and the water.

The water vapor permeability (WVP) and thermal conductivity of polymers are of great significance in personal cooling and even in responding to energy crises. This review attempts to discuss the factors that affecting these two properties at first, and then discusses the relationship between them from the aspects of hydrophilicity, porous .

for water vapor it is given in units of mass of water vapor. Sometimes, the amount of permeant is given in moles. Sometimes the term “diffusion coefficient” is used incorrectly instead of permeability, which are different properties, leading to additional confusion. Another complication involves the water vapor transmission rate (WVTR).

water vapor permeability tester

water vapor permeability of polyethylene

water vapor permeability in packaging

astm e96 perm rating meaning

Resultado da 23 de mai. de 2023 · Hotdog Cloud Game is a free game utility developed by Most fun games platform. This mobile app is a game platform supported .

how to test water vapor permeability distribution|water vapor permeance explained